Investigation of Novel, Internally Hollowed Structured Stainless Steel to Reduce Stress Shielding

Reduce Stress Shielding

DOI:

https://doi.org/10.55672/hij2021pp28-33Keywords:

Structured Stainless Steel, Reduce Stress ShieldingAbstract

There are many aspects that have direct effects on total hip replacement performance (THR), such as material properties, applied loads, surgical approach, femur size and quality, prosthesis design, bone-implant interface etc. One of the purposes to study different structures in THR is reducing the stress shielding. For the current study, an innovative hollow spherical structure is developed for femoral hip stems. The aim is to extract volume in the spherical shape from the stainless-steel hip implant stems, in order to focus solely on correlating with titanium behavior. Internal geometry for the femoral stem is optimized in order to transfer more stress onto the bone. Moreover, the approach involves extracting volume in the spherical shape from the internal structure to reduce stress shielding. A new novel implant is proposed that demonstrated a reduction in stress shielding. The sphered models have a smaller young’s modulus and strength than the solid stainless-steel sample. The spheres in hollowed structures reduce the stress shielding and they transfer more stress onto the bone when compared to the solid stainless-steel models. This approach also involves restructuring a hard material, such as stainless steel, to enhance osseointegration. The reduction of the young’s modulus and stress directly depends on the volume of the hollow spheres in the models; however, there is a certain volume that can be extracted from solid

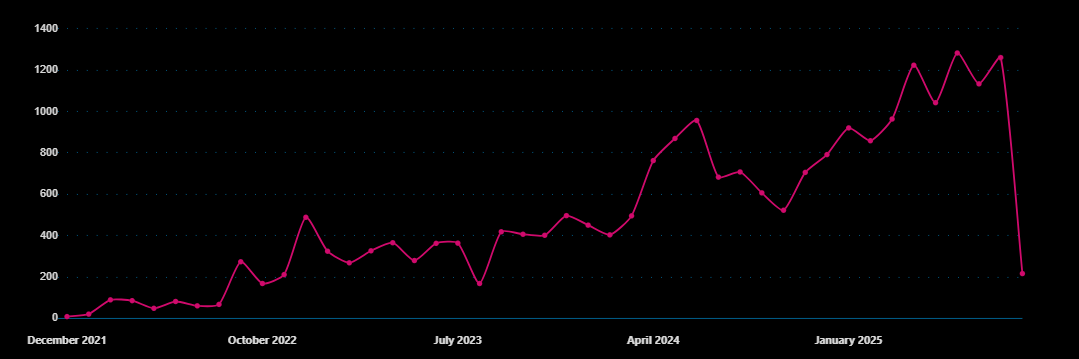

Downloads

References

T. Thielen, S. Maas, A. Zuerbes, D. Waldmann, K. Anagnostakos, and J. Kelm, "Development of a reinforced PMMA-based hip spacer adapted to patients’ needs," Medical Engineering & Physics, vol. 31, pp. 930–936, 2009.

M. Niinomi, "Metallic biomaterials," J Artif Organs, vol. 11, no. 3, pp. 105-110, 2008.

M. Karanjai, R. Sundaresan, G. V. N. Rao, T. R. R. Mohan , and B. P. Kashyap, "Development of titanium based biocomposite by powder metallurgy processing with in situ forming of Ca–P phases," Materials Science and Engineering: A, vol. 447, no. 1-2, pp. 19-26, 2007.

C. Bitsakos, J. Kerner, I. Fisher, and A. A. Amis, "The effect of muscle loading on the simulation of bone remodelling in the proximal femur," Journal of Biomechanics, vol. 38, no. 1, pp. 133–139, 2005.

P. Diegel, A. Daniels, and H. Dunn, "Initial effect of collarless stem stiffness on femoral bone strain," The Journal of arthroplasty, vol. 4, no. 2, pp. 173-178, 1989.

H. E. Jergesen and J. W. Karlen, "Clinical outcome in total hip arthroplasty using a cemented titanium femoral prosthesis," J. Arthroplasty, vol. 17, no. 5, pp. 592–599, 2002.

C. Mattheck, U. Vorberg, and C. Kranz, "Effects of hollow shaft endoprosthesis on stress distribution in cortical bone," Biomed Tech, vol. 35, no. 12, pp. 316-319, 1990.

J. Schmidt and H. Hackenbroch, "The Cenos hollow stem in total hip arthroplasty: first experiences in a prospective study," Arch Orthop Trauma Surg, vol. 113, no. 3, pp. 117-120, 1994.

S. Gross and E. W. Abel, "A finite element analysis of hollow stemmed hip prostheses as a means of reducing stress shielding of the femur," Journal of Biomechanics, vol. 34, no. 8, pp. 995-1003, 2001.

P. Chang et al., "Design and analysis of robust total joint replacements: finite element model experiments with environmental variables," Journal of Biomechanical Engineering, vol. 123, pp. 239-246, 2001.

M. I. Z. Ridzwan, S. Shuib, A. Y. Hassan, A. A. Shokri, and M. N. Mohamad Ibrahim, "Problem of Stress Shielding and Improvement to the Hip Implant Designs: A Review," Journal of Medical Sciences, vol. 7, pp. 460-467, 2007.

M. Sanami, N. Ravirala, K. Alderson, and A. Alderson, "Auxetic materials for sports applications," ScienceDirect, vol. 72, pp. 453 – 458, 2014.

M. Sanami, "AUXETIC MATERIALS FOR BIOMEDICAL APPLICATIONS," University of Bolton, Bolton2015.

O. Duncan et al., "Review of auxetic materials for sports applications: Expanding options in comfort and protection," Applied Sciences, vol. 8, no. 6, p. 941, 2018.

C. Moroney, A. Alderson, T. Allen, M. Sanami, and P. Venkatraman, "The application of auxetic material for protective sports apparel," in Multidisciplinary Digital Publishing Institute Proceedings, 2018, vol. 2, no. 6, p. 251.

H. Wang and J. Y. Lim, "Metal-ceramic bond strength of a cobalt chromium alloy for dental prosthetic restorations with a porous structure using metal 3D printing," Computers in biology and medicine, vol. 112, p. 103364, 2019.

J.-H. Lin, C. H. He, M.-C. Lee, Y.-S. Chen, and C.-W. Lou, "Sports protective elastic knits: structure design and property evaluations," The Journal of The Textile Institute, vol. 111, no. 3, pp. 424-433, 2020.

Published

How to Cite

Issue

Section

License

Copyright (c) 2021 HyperScience International Journal

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

Google Scholar

Google Scholar  Crossref

Crossref  Scopus

Scopus  WorldCat

WorldCat  ORCID

ORCID  Scilit

Scilit  Mendeley

Mendeley  Internet Archive

Internet Archive