Multi-domain Vibrations Response of Externally Excited Fluid Conveyer Pipe in Industrial Steam Generator

Engineering

DOI:

https://doi.org/10.55672/hij2022pp36-45Abstract

Electric power is an indispensable consumer commodity for a little over a century now as all electric equipment in dwellings, commercial, and industry sectors are essentially dependent on electricity. Heat recovery steam generator, HRSG is an important system in combined cycle power plants. Indeed, excess vibrations induced on such devices may gradually lead to fatigue failure that affect the process of power output. This work investigates, models, and simulates the vibrations response of a fluid carrier pipe housed inside the cavity of the system while experiencing highly pressurized nearly perpendicular external force of extremely hot flue gas on the outside and pressurized water and water vapour from the inside. Transient and steady-state vibrations from initial conditions and the forcing function analysis are performed to account for the variation of damping, amplitude, and frequency responses of the system. Initial parameters used in the systems’ model are from industry subsequent to the OEM instructions. However, we introduce a new set of parameter values so as to observe the vibrational behaviour by varying these parameters. The purpose of performing a parameter-based vibration analysis is that parameter variation may point to different responses in the system. Indeed, this in turn indicates which set of parameters are suitable for rectifying the primary causes of undesired vibrations. To account for the consequence of mass flowrate, the model covers low pressure, intermediate pressure, and high-pressure constituents. The results obtained from the model are for the relationships of amplitude and phase angle as functions of frequency of the system. From these data, different interactions of quantities such as force, damping ratio, and number of dampers and vibration supports are observed. These results implores the implementation of new set of parameters to improve the agility of the system and minimize the impact of excess vibrations.

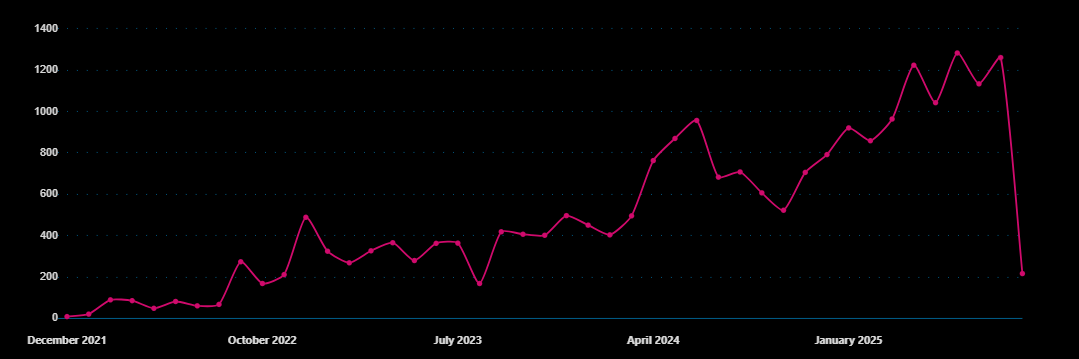

Downloads

References

[1] F. Carazas, C. Salazar, and G. J. E. Souza, "Availability analysis of heat recovery steam generators used in thermal power plants," vol. 36, no. 6, pp. 3855-3870, 2011.

[2] A. Benato, A. Stoppato, and A. J. E. Mirandola, "Dynamic behaviour analysis of a three pressure level heat recovery steam generator during transient operation," vol. 90, pp. 1595-1605, 2015.

[3] N. Petchers, Combined heating, cooling & power handbook: technologies & applications: an integrated approach to energy resource optimization. River Publishers, 2020.

[4] A. Ong'Iro, V. Ugursal, A. Al Taweel, and J. J. A. T. E. Walker, "Modeling of heat recovery steam generator performance," vol. 17, no. 5, pp. 427-446, 1997.

[5] G. Electric. Combined cycle power plant: How it works, GE power generation, [Online] [Online]. Available: https://powergen.gepower.com/resources/knowledge-base/combined-cycle-power-plant-how-it-works.html

[6] V. Ganapathy, Industrial boilers and heat recovery steam generators: design, applications, and calculations. CRC Press, 2002.

[7] M.-N. Dumont, G. J. C. Heyen, and c. engineering, "Mathematical modelling and design of an advanced once-through heat recovery steam generator," vol. 28, no. 5, pp. 651-660, 2004.

[8] M. Plis and H. Rusinowski, "Mathematical modelling of single pressure heat recovery steam generator," in Proceedings of the 2015 16th International Carpathian Control Conference (ICCC), 2015, pp. 399-404: IEEE.

[9] M. Plis and H. Rusinowski, "Modelling and simulation of the effect of ambient parameters on the performance of a combined cycle gas turbine power plant," in 2016 17th International Carpathian Control Conference (ICCC), 2016, pp. 590-595: IEEE.

[10] M. Plis and H. J. I. T. o. I. A. Rusinowski, "Adaptive simulation model of a double-pressure heat recovery steam generator for current optimization in control systems," vol. 53, no. 1, pp. 530-537, 2016.

[11] B. Aklilu and S. J. A. T. E. Gilani, "Mathematical modeling and simulation of a cogeneration plant," vol. 30, no. 16, pp. 2545-2554, 2010.

[12] P. Sindareh-Esfahani, A. Ghaffari, and P. J. A. t. e. Ahmadi, "Thermodynamic modeling based optimization for thermal systems in heat recovery steam generator during cold start-up operation," vol. 69, no. 1-2, pp. 286-296, 2014.

[13] A. Behbahani-Nia, M. Bagheri, and R. J. A. T. E. Bahrampoury, "Optimization of fire tube heat recovery steam generators for cogeneration plants through genetic algorithm," vol. 30, no. 16, pp. 2378-2385, 2010.

[14] S. Bracco, M. Troilo, and A. Trucco, "A simple dynamic model and stability analysis of a steam boiler drum," ed: SAGE Publications Sage UK: London, England, 2009.

[15] F. Alobaid, J. Ströhle, B. Epple, and H.-G. J. A. E. Kim, "Dynamic simulation of a supercritical once-through heat recovery steam generator during load changes and start-up procedures," vol. 86, no. 7-8, pp. 1274-1282, 2009.

[16] F. Alobaid, S. Pfeiffer, B. Epple, C.-Y. Seon, and H.-G. J. E. Kim, "Fast start-up analyses for Benson heat recovery steam generator," vol. 46, no. 1, pp. 295-309, 2012.

[17] H. J. C. E. R. Goyder and Design, "Flow-induced vibration in heat exchangers," vol. 80, no. 3, pp. 226-232, 2002.

[18] M. Pettigrew, C. J. J. o. f. Taylor, and structures, "Vibration analysis of shell-and-tube heat exchangers: an overview—Part 1: flow, damping, fluidelastic instability," vol. 18, no. 5, pp. 469-483, 2003.

[19] M. Pettigrew, C. J. J. o. F. Taylor, and Structures, "Vibration analysis of shell-and-tube heat exchangers: an overview—Part 2: vibration response, fretting-wear, guidelines," vol. 18, no. 5, pp. 485-500, 2003.

[20] S. Khushnood, Z. M. Khan, M. A. Malik, Z. U. Koreshi, M. A. J. N. e. Khan, and design, "A review of heat exchanger tube bundle vibrations in two-phase cross-flow," vol. 230, no. 1-3, pp. 233-251, 2004.

[21] M. Pettigrew, C. Taylor, and N. Subash, "Flow-induced vibration specifications for steam generators and liquid heat exchangers," Atomic Energy of Canada Ltd.1995.

[22] J. C. Jo, M. J. J. N. e. Jhung, and design, "Flow-induced vibration and fretting-wear predictions of steam generator helical tubes," vol. 238, no. 4, pp. 890-903, 2008.

[23] M. Pettigrew, C. Taylor, N. Fisher, M. Yetisir, B. J. N. E. Smith, and Design, "Flow-induced vibration: recent findings and open questions," vol. 185, no. 2-3, pp. 249-276, 1998.

[24] S. S. J. E. A.-W. P. C. Rao, New York, "Mechanical vibrations laboratory manual," 1995.

[25] Y. A. Cengel, S. Klein, and W. Beckman, Heat transfer: a practical approach. WBC McGraw-Hill Boston, 1998..

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Hyperscience International Journal

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

Google Scholar

Google Scholar  Crossref

Crossref  Scopus

Scopus  WorldCat

WorldCat  ORCID

ORCID  Scilit

Scilit  Mendeley

Mendeley  Internet Archive

Internet Archive